47B HYDROPHILIC BUTYL WATERSTOP SEAL

Description

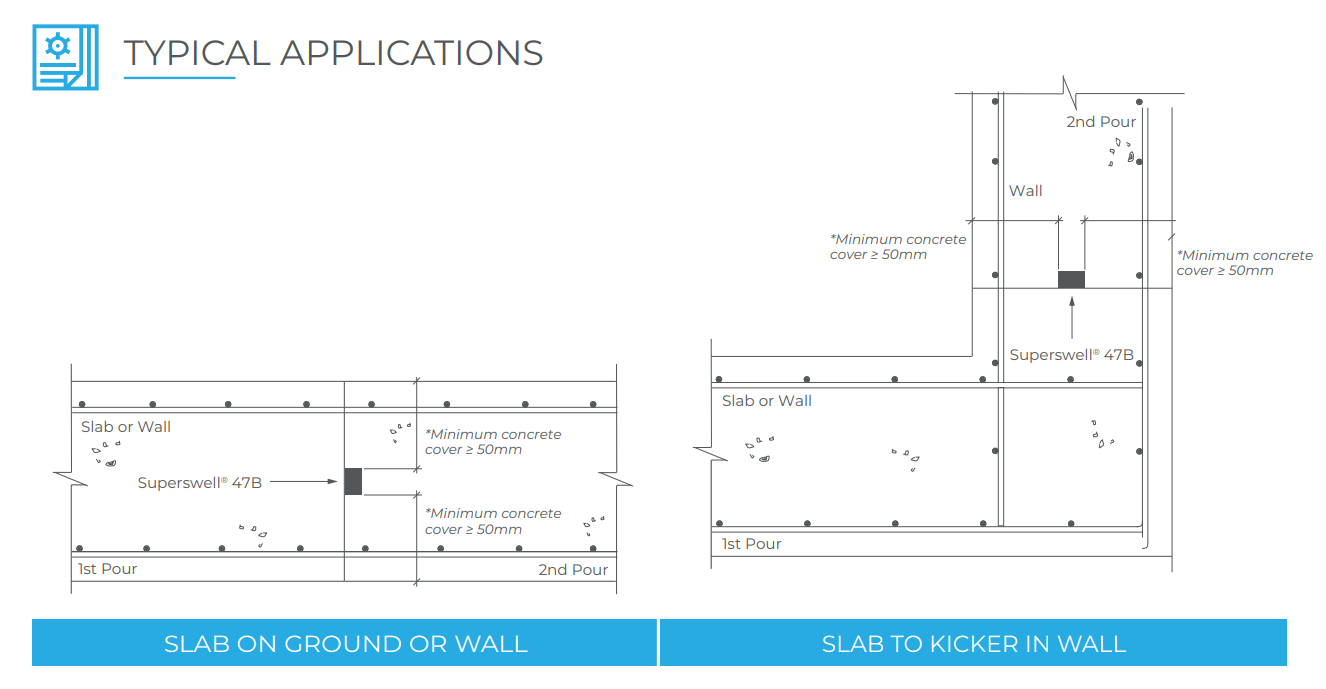

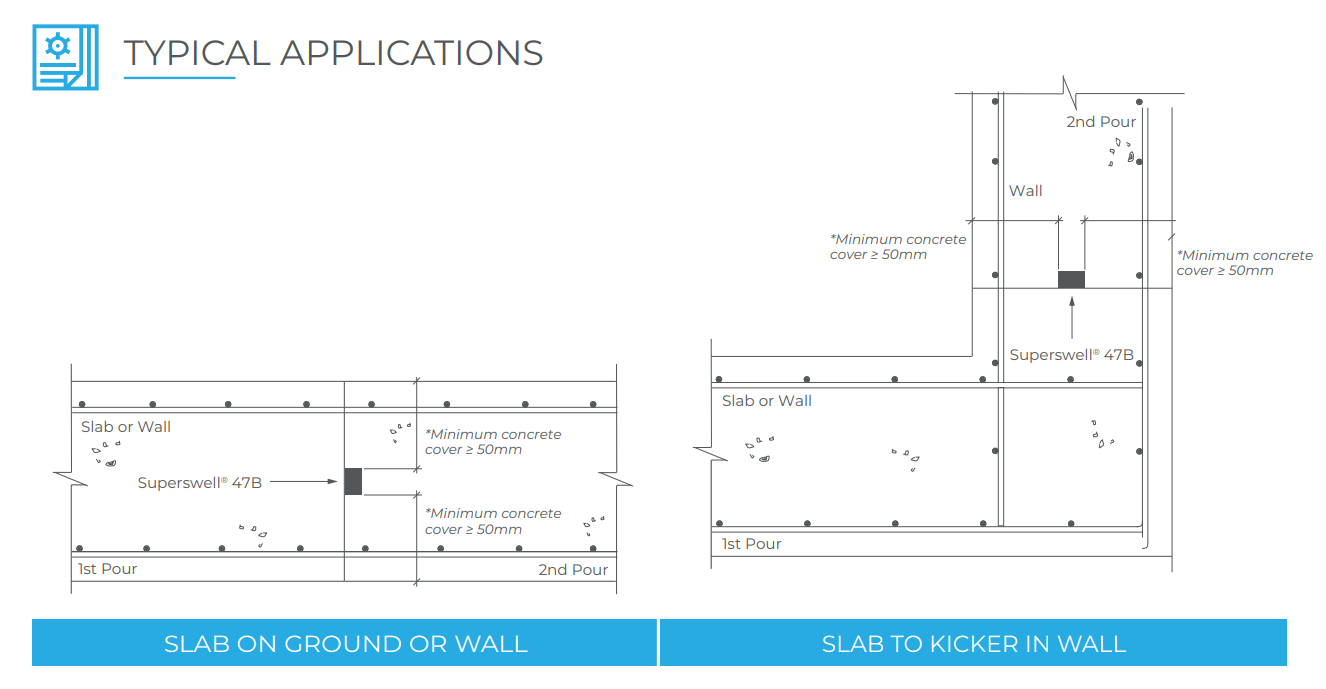

Superswell® 47B Hydrophilic Butyl Waterstop Seal is a unique sealing compound which expands in a controlled fashion when exposed to moisture, forming a compression seal in concrete joints. Superswell® 47B is ideal for use in horizontal and vertical construction joints for cast in-situ concrete structures. Superswell® 47B is manufactured utilising a specialised mixing process which encapsulates hydrophilic materials into a Butyl base creating a controlled, moisture-activated seal. The product has the structural integrity and the long term durability features of Butyl, as well as the ability to expand to create a SELF-HEALING JOINT WATERSTOP SEAL. Superswell® 47B has been tested to withstand a 60 metre (6.0 Bar) head of water pressure in potable and salt water conditions and can expand up to 180% after 30 days of continual submersion in distilled water. Superswell® 47B complies to NSF/ANSI Standard 61 Drinking Water System Components – Health Effects, ensuring Superswell® 47B is safe for use in drinking water applications. Therefore, it is suitable to use in various potable water retaining structures like water tanks, swimming pools and reservoirs.

Unlike many of the traditional clay-based products, Superswell® 47B being hydrophilic polymer based, will not expand to a point that the hydration process itself leads to the possible “disintegration” of the waterstop due to its expansion control system. This is an important issue when the engineers are looking for a seal in vertical construction joints where the joint can open due to excessive shrinkage in the concrete. In-field experience has proven that products which continually expand, may lose their structural integrity and begin to wash away from the joint when subject to a constant flow of water or from high water pressure. Superswell® 47B does not expand prematurely from the wet weather due to its unique expansion control system which also means it doesn’t expand from the water in the fresh concrete when poured against it, which helps minimize any pre-expansion if the joint becomes ponded with water. Superswell® 47B is very unique in that it can be installed by embedding it into wet concrete of the first pour as the concrete upon drying bonds very well to the Butyl Seal.

Due to its Butyl properties, it bonds to both concrete surfaces (1st and 2nd pour) creating a gasket seal first, when used in conjunction with CJ-100 Adhesive. The wet concrete from the 2nd pour bonds tenaciously to Superswell® 47B. Superswell® 47B has been tested to withstand a 60 metre (6.0 Bar) head of water pressure in potable and salt water conditions and can expand up to 180% after 30 days of continual submersion in distilled water. Superswell® 47B complies to NSF/ANSI Standard 61 Drinking Water System Components – Health Effects, ensuring Superswell® 47B is safe for use in drinking water applications. Therefore, it is suitable to use in various potable water retaining structures like water tanks, swimming pools and reservoirs.

Uses

Water retaining structures

-

Water tanks

-

Water treatment plants

-

Sewage treatment plants

-

Swimming pools

-

Dams and spillways

-

Reservoirs

-

Bund walls

Water excluding structures

-

Basements

-

Underground car parks

-

Tunnels

-

Retaining walls

-

Suspended slabs

-

Below ground slabs

-

Roof & podium slabs

Other

Advantages

-

Conforms easily for installation onto rough or smooth concrete surfaces

-

Excellent adhesion to concrete with CJ-100 Adhesive

-

Allows concrete to gain strength before expansion due to built-in expansion control system

-

Use in horizontal and vertical construction joints

-

Long term durability & integrity

-

Can be bedded into the wet concrete of the first pour for installation

-

No compaction or displacement problems

-

Unaffected by repeated wet and dry cycles

-

Has the ability to bond to both concrete surfaces. No on-site welding required

-

Can withstand 60 metres (6.0 Bar) of hydrostatic head pressure

-

Ability to handle long-term exposure to the environment prior to the 2nd pour taking place

-

Non-toxic and requires no special handling

-

NSF Certified for use in potable water applications

-

Very easy to handle and install

Application

Colour

Packaging