How to Choose the Perfect Industrial Concrete Driveway in Sepang (2026 Guide)

Industrial Concrete Driveway

Industrial Concrete Driveway

Planning an industrial concrete driveway in Sepang requires the right materials, thickness, and experienced contractors. Sepang’s tropical climate and heavy-load demands make proper design and surface treatment essential for long-term durability.

This 2025 guide provides practical insights on recommended concrete thickness, suitable surface finishes, and protective sealers, helping property owners choose solutions that withstand heavy usage, weather exposure, and time. Make informed decisions to ensure a strong, durable, and cost-effective industrial concrete driveway for your Sepang property.

Why an Industrial Concrete Driveway is Ideal for Sepang

The industrial sector in Sepang needs building materials that can handle extreme conditions and provide value over time. Industrial concrete driveways have become the top choice for factories, warehouses, and commercial properties in this region. Let me explain why.

Industrial concrete driveways are ideal for high-traffic environments, especially in Sepang’s manufacturing and logistics zones. Designed for heavy loads and constant vehicle movement, they provide the strength and stability businesses rely on.

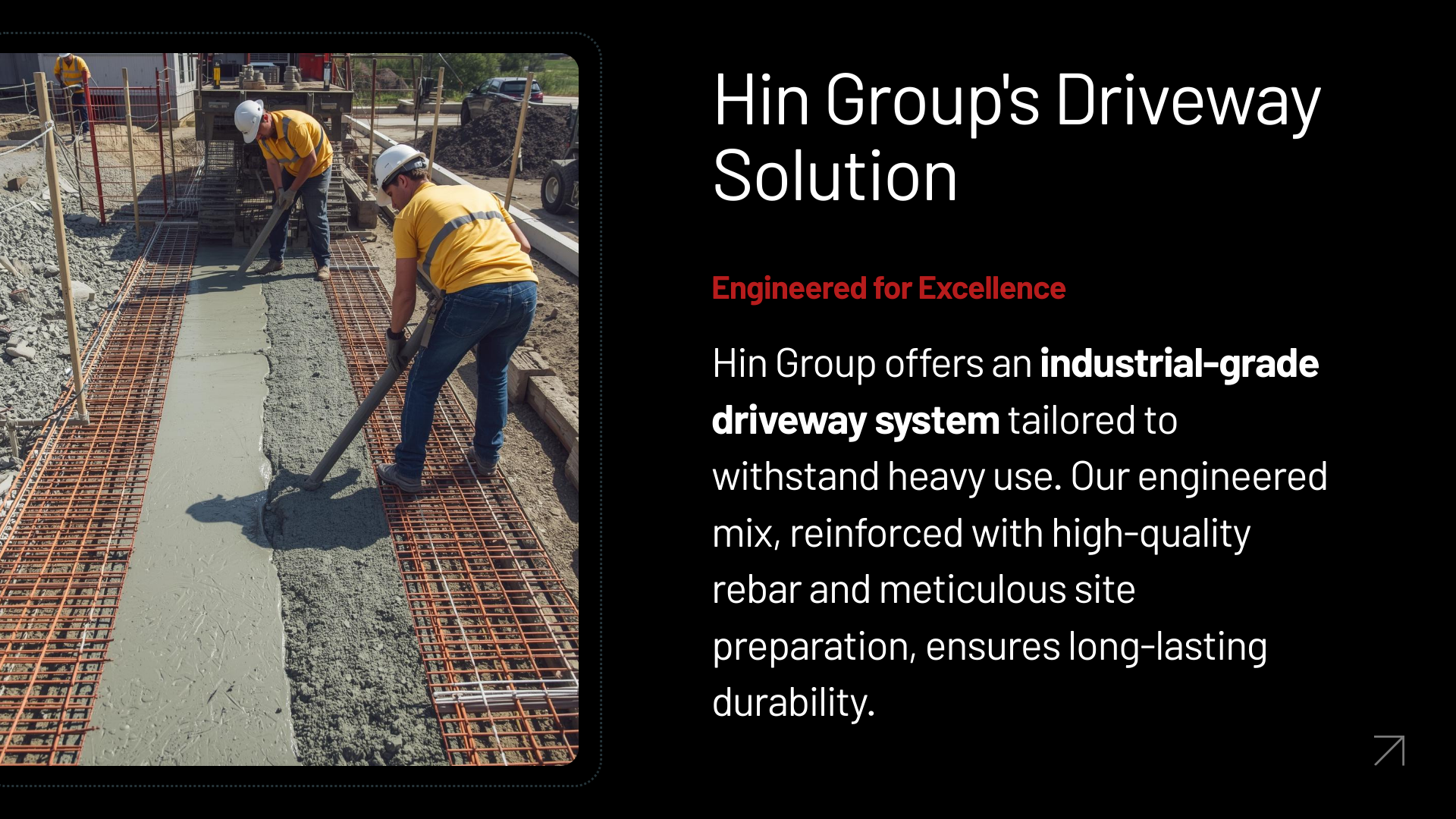

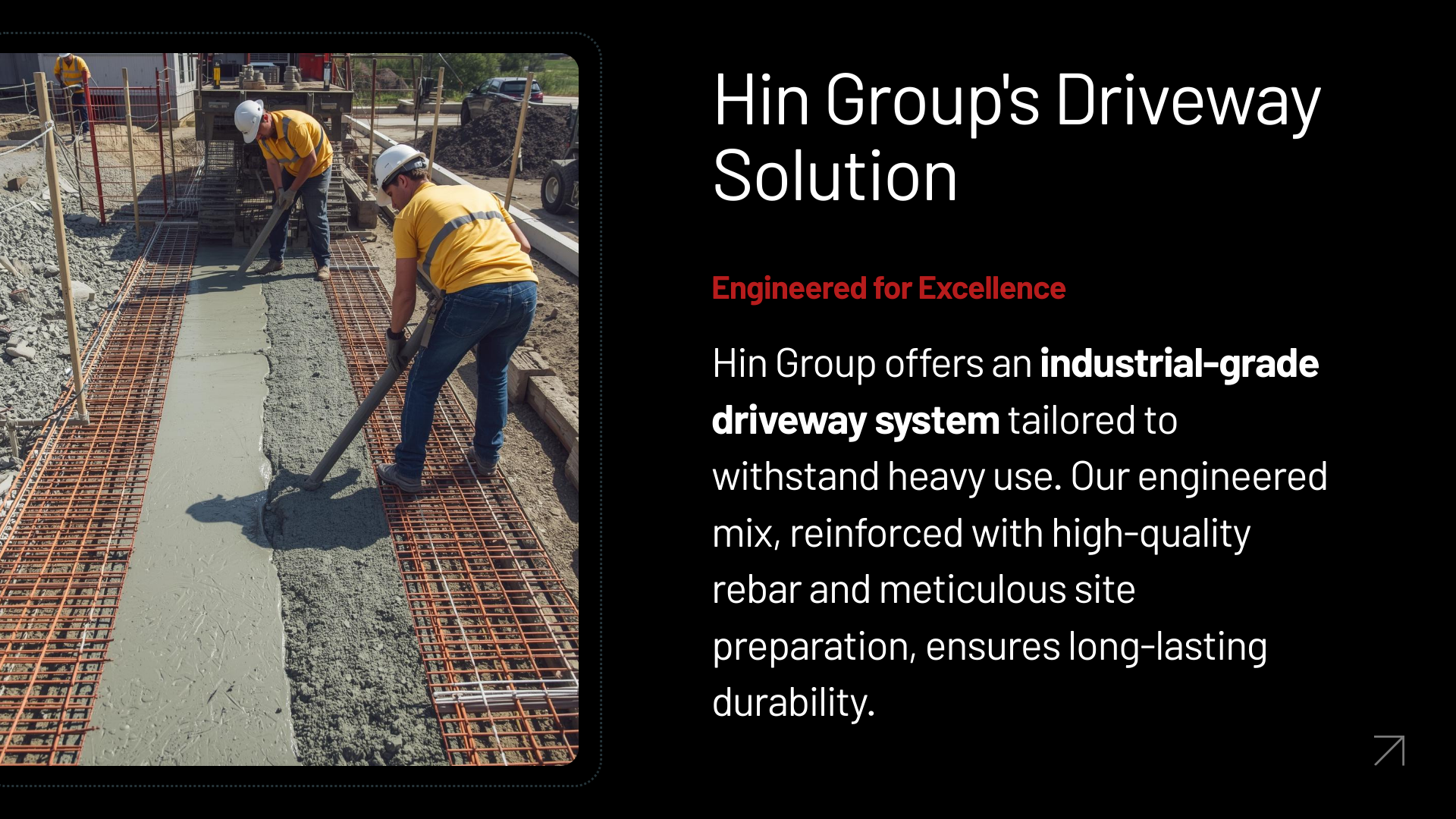

Using industrial-grade ready-mix concrete (G30–G60) ensures high compressive strength, making these driveways suitable for heavy machinery, delivery trucks, and continuous operations. [1].

The thickness of a concrete driveway becomes most important in industrial settings. Heavy industrial vehicles need 6-8 inches (150-200mm) of thickness. Areas that see constant heavy loads might need 8-12 inches [2]. This extra thickness helps spread weight evenly across the ground below, which stops cracks from forming too early.

Ready-mix concrete can include fiber reinforcement to streamline structural integrity and reduce cracking and shrinkage. This makes it perfect for high-impact areas like factory driveways where you need durability under stress [3].

Weather resistance in Malaysian climate

Sepang's tropical weather creates unique challenges for driveway materials. Concrete stands out from other options because it handles weather so well.

Tropical climate resilience: While asphalt gets soft in extreme heat, concrete stays strong even on Sepang's hottest days. This material won't develop ruts or change shape like other surfaces might [4].

Malaysian ready-mix concrete works well with the region's monsoons and high humidity. A properly installed concrete driveway resists heavy rain, humidity, and strong UV rays [4]. These driveways keep performing whatever the weather throws at them.

Concrete can also get extra protection from various sealers. An industrial concrete driveway sealer adds another layer of defense against moisture and chemicals, helping it last longer in Sepang's tough climate [5].

Malaysia's high humidity and frequent rain make drainage a priority. Smart concrete driveway designs with proper slopes help water run off quickly, unlike other materials that can get damaged by standing water [4].

Low maintenance benefits

in Sepang need very little maintenance, which saves money over time.Industrial concrete driveways

Reduced upkeep requirements: Asphalt driveways need new surfaces every 3-5 years. A well-installed concrete driveway lasts 20-30 years with minimal care. This makes concrete economical for industrial properties that see heavy use [4].

Industrial concrete driveways offer these maintenance advantages:

- They resist chemical spills common in industrial settings

- They need minimal cleaning - just occasional pressure washing

- They rarely need repairs or patching

- They cost less over time despite higher upfront costs

- They resist stains from oil and petroleum products when sealed properly

Sealing every 2-5 years is the main upkeep needed for concrete driveways in Sepang. This simple step keeps water out and makes the surface last much longer [5]. If damage occurs, you can often fix small sections without disrupting the whole driveway.

These combined benefits - outstanding durability, weather resistance, and low maintenance needs - make industrial concrete driveways the smart choice for Sepang's commercial and industrial properties looking for lasting performance and value.

Key Factors to Consider Before Installation

Your industrial concrete driveway's success starts well before the first pour. You need a full picture and proper planning to protect your investment in Sepang's unique conditions. Let's get into the key factors that will determine how well your driveway performs over time.

Site assessment and soil condition

A detailed site evaluation helps you spot potential issues and make the right design choices. Your soil's composition plays a big role in your industrial concrete driveway's performance.

The soil's bearing capacity is one of the key factors that determines pavement thickness [6]. Soil samples need testing for strength before construction begins. The Rebar Or BRC serves as the main parameter [7]. This test shows how much load the soil can bear - a lower value means weaker soil [7].

Different soil types create unique challenges:

- Clay soils: These expand when wet and shrink when dry, which stresses concrete structures [8]

- Sandy soils: They drain well but might need extra base preparation to avoid settling [8]

- Loamy soils: These give you a good mix of stability and drainage features [8]

Professional soil testing reveals moisture content, compaction rates, and organic materials. These factors directly affect the concrete thickness and reinforcement you'll need [8]. A design value of 3 or less shows poor soil quality.

This soil needs removal to a depth of 12-18 inches and replacement with stronger material, or treatment with lime or cement [7]makes a big difference. The area needs trimming, with all rock, debris, and vegetation removed. The subgrade should compact to a uniform minimum density of 95% of the maximum theoretical density Proper subgrade preparation[7].

Expected load and traffic

The vehicles using your industrial driveway and how often they use it determine thickness and reinforcement needs. Industrial pavements usually handle heavy loads, so proper design is vital [7].

Industrial settings with heavy trucks and equipment typically need concrete thickness of 6-8 inches (150-200mm) [9]. Load analysis should include both static loads from parked vehicles and dynamic loads during movement [9].

Vehicle weight classes affect design requirements substantially:

- Standard passenger vehicles (3,000-6,000 lbs): Minimum 4-inch thickness [9]

- Medium-duty vehicles (10,000-26,000 lbs): 6-inch reinforced concrete [9]

- Heavy-duty vehicles (exceeding 26,000 lbs): 8-12 inches thickness [9]

Note that one fully loaded 80,000-pound truck equals the pavement wear of 9,600 cars [7]. This is a big deal as it means that accurate traffic type, weight, and frequency estimates are essential for proper design.

Drainage and slope planning

Good drainage stops water from weakening your industrial concrete driveway. Surface and subsurface drainage systems need installation early in construction [6].

Pavements need a minimum grade or cross-fall of 1% (1 in 100), or 10mm per meter for proper drainage [10]. Industrial driveways should have a longitudinal grade maximum of 1:10 and match footpath levels where needed [11].

You'll need transition gradients when grade changes exceed 12.5% [1]. Main Roads WA suggests a maximum grade of 5-8% for commercial vehicles to avoid damage [1].

Water falling on the pavement surface must flow to curb and gutter systems or ditches [7]. Water should not compromise overall strength whether it comes through the surface, sides, or underneath [7].

Sites with tough drainage conditions might need French drains or grated trench drains connected to channels or gullies [2]. These drainage systems become especially important when the site slopes toward the road [2].

Experienced industrial concrete contractors who know Sepang's drainage challenges can create economical solutions that work for your property's specific needs.

What Thickness Concrete for Driveway Works Best?

The right concrete thickness can make or break an industrial driveway project in Sepang. Your specific needs will determine the sweet spot between durability, cost, and performance.

Standard thickness for industrial use

Most simple industrial projects in Sepang need 5 to 6 inches (125-150mm) of concrete. This works well for light to medium trucks and occasional heavy vehicles.

Sites with frequent commercial and industrial traffic need 7 inches or thicker concrete [12]. Some heavy industrial sites might need custom calculations based on their specific loads.

These numbers match international standards. Australian guidelines suggest 150mm to 200mm (about 6-8 inches) for commercial driveways depending on the expected load [13].

The sub-base is just as vital as the concrete's thickness. A supports the concrete slab like a foundation proper sub-base[14]. Professional contractors will:

- Remove all vegetation and debris

- Compact the soil fully

- Install a granular base layer (usually crushed stone)

- Grade properly for drainage before pouring concrete

How thick should a concrete driveway be for heavy vehicles

Driveways that support heavy vehicles need extra thickness to avoid early failure. The concrete must be thicker if you expect regular traffic from garbage trucks, delivery vehicles, or industrial equipment.

Heavy vehicles need specific thicknesses:

- 6-inch thickness: This is the minimum if you'll have occasional heavy commercial vehicles [3]

- 8-inch thickness: You'll need this for regular heavy truck traffic [3]

- 10-12 inches: Loading docks or dumpster pads with constant heavy loads need this much [3]

becomes more important as the concrete gets thicker. Heavy-duty industrial applications need:Steel reinforcement

- Steel rebar or wire mesh at the right height

- At least 30mm concrete cover from the top

- Control joints in strategic spots to handle stress and prevent cracks [5]

The Portland Cement Association stresses that industrial driveways need even thickness on well-prepared surfaces with proper drainage slopes [12]. Missing any of these elements can cause even the thickest concrete to fail early.

Impact of thickness on longevity

Concrete thickness directly affects how long your driveway will last. A well-built concrete driveway can serve you for 20 to 40 years, largely thanks to its thickness and construction quality [15].

Your driveway's thickness helps it handle three main challenges:

- Weight distribution: Thicker slabs spread vehicle weight better across the soil

- Environmental resistance: More thickness helps fight freeze-thaw cycles and temperature changes

- Structural integrity: Thicker concrete resists cracks better under stress

Thickness plays a vital role in preventing common failures. Thin concrete shows problems through cracks in tire paths (poor weight distribution), crumbling edges (weak reinforcement), and water pooling (settled surface) [4].

Cutting corners on thickness to save money now will cost you more later. A 150mm (6-inch) concrete driveway costs more upfront than a 100mm (4-inch) one, but it might last twice as long in industrial settings [4].

The Ohio Concrete Association says that "concrete thickness isn't just a technical detail—it's the backbone of durability" [16]. Industrial sites in Sepang's tough climate will get better value from proper thickness through longer life and lower maintenance costs.

Choosing the Right Materials and Finishes

Your choice of concrete materials and finishes is a vital step to build an industrial concrete driveway that works well in Sepang's tough conditions. The right choices will affect how well your investment performs and how long it lasts.

Types of concrete mixes for industrial driveways

Industrial projects need concrete mixes that are stronger than residential ones. Heavy-duty industrial driveways in Sepang work best with concrete grades between C30 to C40. These grades give excellent compressive strength in areas with frequent, heavy vehicle traffic [17].

The ratio of components determines how well the concrete performs:

- 1:2:4 ratio (one part cement, two parts sand, four parts aggregate): This works best for slabs and flooring where you need balanced strength and workability [18]

- 1:2:3 ratio (one part cement, two parts sand, three parts aggregate): You can use this for general construction [18]

- 1:1.5:3 ratio (one part cement, 1.5 parts sand, three parts aggregate): This is your best bet for high-strength projects where durability matters most [18]

Industrial settings with heavy vehicle loads need concrete mixes with angular aggregates instead of rounded ones. Crushed gravels and stone are better than natural gravels for joint performance through millions of load cycles [17].

Surface finishes: broom, exposed aggregate, stamped

Your industrial concrete driveway's surface finish affects both its looks and how well it works. Here are three popular options to think over:

Broom finish is the most practical choice for industrial driveways. You create it by dragging a specialized broom across fresh concrete. This creates fine, parallel ridges that improve traction. The textured surface helps prevent slips even in wet conditions, which is perfect for Sepang's rainy weather. This finish is affordable and easy to apply [20].

Exposed aggregate finish shows the natural stones in the concrete mix by washing away the top cement layer. You get a textured, eye-catching surface that's great for preventing slips while looking good [21]. Local aggregates give you various color options and cut down on transportation costs while keeping the design authentic [21]. This finish is ideal when you want durability, good grip, and natural looks [22].

Stamped concrete gives you the look of expensive materials like brick, stone, or tile but costs much less. The patterns go into the surface before it hardens [23]. It looks great, but you'll need to add anti-slip additives to the sealer. Smooth stamped surfaces can get slippery when wet [23]. This option is great for businesses that want to make a design statement while keeping things functional.

Safety comes first when picking finishes for an industrial concrete driveway. Good slip resistance is essential in industrial spaces where oil spills or wet conditions happen often.

The Coefficient of Friction (COF) measures slip resistance. Industrial applications need ratings of 0.6 or higher to be safe [24]. Exposed aggregate and broom finishes naturally exceed this threshold. Smooth finishes usually need extra treatment to be safe enough [25].

These factors affect how slip-resistant concrete surfaces are:

- Surface texture: Rough textures like broom finishes give better grip

- Aggregate exposure: Exposed aggregate creates more contact points for better grip

- Sealers: Some can make surfaces more slippery unless you add anti-slip materials

You can make any concrete finish safer by:

- Adding glass beads, crushed glass, or carborundum between sealer coats [25]

- Using rougher broom finishes where it gets wet

- Making sure water drains properly

Australian Standards suggest two ways to test slip resistance: wet pendulum tests for both shoe and barefoot conditions, and ramp tests where people walk on slopes [25]. These tests make sure your industrial driveway is safe no matter which finish you pick.

Your materials and finishes should look good while meeting practical needs for safety and durability in your industrial space. Working with contractors who know Sepang's climate will help you get the best results for your needs.

Understanding Costs and Budgeting Smartly

Smart planning helps you avoid financial surprises while budgeting your industrial concrete driveway project. A clear understanding of costs will help you make better decisions and get more value in Sepang's competitive construction market.

Average cost per square meter in Sepang (2026)

The price of industrial concrete driveways depends on size, thickness, and finish requirements. Standard installations in Sepang cost between MYR 17.87 and MYR 31.26 per square foot. Premium or decorative finishes might cost up to MYR 67.00 per square foot [26].

Here's what you should budget:

- A single-car driveway (about 200 square feet) costs MYR 3573.10 to MYR 7146.21 [26]

- A standard two-car driveway (about 400-600 square feet) ranges from MYR 10272.68 to MYR 20545.35 [26]

Raw materials make up a big part of the cost. Ready-mix concrete (Grade 30, granite) costs MYR 328.43 per cubic meter in Malaysia [27]. Your driveway's thickness will affect this base cost.

Hidden costs to watch out for

Property owners often miss several key expenses beyond the basic square footage calculations:

Site preparation costs can surprise you, especially with tough terrain. You might need to spend MYR 5359.66 or more on proper excavation and soil stabilization [28]. This matters even more given Sepang's varied landscape.

Permit and inspection fees often catch people off guard. Most contractors don't include these mandatory industrial installation fees in their quotes [28].

Drainage solutions are crucial yet often underfunded. A proper water management system adds 10-15% to your total cost but protects your investment from early damage [6].

Delivery charges add MYR 111.66 per square foot [28]. Large industrial projects need multiple trucks, so this adds up quickly.

Tips to stay within budget

You can manage costs without compromising your industrial concrete driveway's quality:

- Get multiple detailed quotes from trusted contractors. Make sure they list all possible expenses including site prep, reinforcement, and finishing [29]

- Time your project right – contractors often offer better prices during slow construction periods to keep their teams busy [6]

- Set aside a contingency fund of about 10% above your estimate for unexpected costs or changes [29]

- Choose quality upfront – good thickness and reinforcement costs less than future repairs proper thickness and reinforcement[30]

- Do some prep work yourself like clearing plants or debris to save on labor costs [29]

Remember, skimping on basics like proper thickness or concrete quality will cost more over time. A well-built industrial concrete driveway should last 25-50 years with minimal upkeep [30].

How to Choose the Right Industrial Concrete Contractors

A qualified contractor can make or break your industrial concrete driveway project in Sepang. Your driveway's longevity depends on choosing the right professional who knows what they're doing.

What to look for in a contractor

You should focus on three key qualities to review . Reliability comes first - you need contractors with solid track records who finish projects on time and keep you updated about deadlines and changes in production industrial concrete contractors[31].

Skills and specialties matter too. Look for contractors who specialize in industrial concrete work rather than general concrete jobs. The best ones have direct access to concrete materials and don't rely much on other companies [31].

Customer feedback tells the real story. Good contractors receive positive ratings from past clients about their completion times, pricing, customer service, cleanliness, and communication [31].

Experience speaks volumes. Contractors who've been in business for several years know their craft well and have solved many complex problems [34]. Ask to see their previous industrial projects - this shows what they can really do with similar installations.

Questions to ask before hiring

Make sure you ask these key questions before signing any contract:

- "Are you licensed, insured, and bonded?" This protects your interests if accidents happen during work [8].

- "How long will the project take and when can you start?" This helps you plan better [8].

- "What will you use for my driveway?" Industrial projects need 4,500 PSI or higher strength concrete[35].

- "What type of reinforcement will you use?" Quality contractors should mention rebar, not just wire mesh [35].

- "Can you provide references from similar industrial projects?" Don't forget to contact these references yourself [36].

- "Will you or someone else manage the project directly?" You need to know who's in charge and who to contact if problems come up [8].

The time you spend checking industrial concrete contractors saves money later. The right contractor brings technical expertise and becomes part of your team through quality work, reliable schedules, and clear accountability.

Installation Process: What to Expect

The installation process of your industrial concrete driveway needs proper understanding. This knowledge helps you set realistic expectations and plan better. You can prepare better and track progress when you know what happens at each stage.

Step-by-step overview

Your industrial concrete driveway installation follows a clear sequence:

- Site evaluation and preparation - Contractors check soil conditions, set up proper drainage, and prepare the subbase. This foundation phase requires removal of existing material, slope grading, and installation of 4-6 inches of compacted base material [9].

- Formwork and reinforcement - Contractors place forms along edges and position reinforcement (steel mesh, rebar, or fiber). This step helps control cracking and improves load distribution [9].

- Concrete placement - The team delivers ready-mix concrete and places it systematically from the farthest point. They consolidate it to remove air voids and screed it for uniform thickness [9].

- Finishing operations - The concrete gets bull-floated after placement. The team tools the edges, creates control joints, and applies final finishing (broom, stamped, or exposed aggregate) [9].

Timeline from prep to curing

A typical industrial driveway installation takes:

- Planning and original preparation: 1-2 days [37]

- Excavation and base preparation: 1-2 days [37]

- Formwork and reinforcement: 1 day [37]

- Concrete pouring and finishing: 1 day [37]

- Initial curing: 24-48 hours before light foot traffic [9]

- Full curing: 7-10 days minimum before vehicle traffic [9]

- Complete strength development: 28 days [9]

Common delays and how to avoid them

Several factors can slow down the installation process:

- Weather interruptions - Plan your work during dry seasons and keep protective coverings ready [7]

- Material shortages - Get your materials early and build relationships with multiple suppliers [7]

- Equipment breakdowns - Keep equipment well-maintained and have backups ready [7]

- Inspection delays - Submit permits early and book inspections right away [7]

You can minimize these delays by working with experienced industrial concrete contractors who know Sepang's conditions well.

Conclusion

The best industrial concrete driveway for your Sepang property depends on three key factors - durability, functionality, and long-term value. This piece shows how the right thickness specs form the foundation of lasting performance. Medium industrial use needs 6-8 inches while heavy-duty applications require 8-12 inches.

Concrete's weather resistance makes it perfect for Sepang's tropical climate. The material holds up well against heat, heavy rain, and humidity with proper installation and care. It also needs minimal upkeep, which saves you money throughout your driveway's life.

Your concrete driveway project needs a thorough site check before work begins. The way your installation performs over decades depends on soil conditions, expected vehicle loads, and drainage plans. Skipping these vital prep steps often causes early failure, no matter how good your materials are.

You need to pick the right concrete mixes and surface finishes. A good combination gives you slip resistance, visual appeal, and toughness under industrial use. Understanding all costs, including hidden ones, helps you plan your budget without surprises.

Finding the right contractor might feel daunting. Yet picking experienced pros who know Sepang's requirements pays off through quality work and fewer issues. Ask specific questions about their experience, materials, and how they plan to reinforce the concrete.

This guide gives you the knowledge to make smart choices about your industrial concrete driveway project. Good planning now means decades of reliable service, even under Sepang's most demanding conditions.

Key Takeaways

Selecting the right industrial concrete driveway in Sepang requires careful consideration of thickness, materials, and local climate conditions to ensure decades of reliable performance.

• Thickness is critical:

Industrial driveways need 6-8 inches for medium use and 8-12 inches for heavy vehicles to prevent premature failure and cracking.

• Site preparation determines success:

Proper soil assessment, drainage planning, and subgrade preparation are essential before installation to avoid costly future repairs.

• Choose experienced contractors wisely:

Verify certifications, industrial experience, and references to ensure quality workmanship that meets Sepang's specific requirements.

• Sealing extends lifespan significantly:

Apply industrial-grade sealers every 2-3 years to protect against moisture, chemicals, and UV damage in Malaysia's tropical climate.

• Budget for hidden costs:

Factor in site preparation, permits, drainage solutions, and delivery charges which can add 15-20% to base installation costs.

The combination of proper planning, quality materials, and professional installation creates an industrial concrete driveway that withstands Sepang's demanding conditions while delivering exceptional long-term value for your business operations.

FAQs

Q1. What thickness of concrete is recommended for an industrial driveway in Sepang?

For industrial driveways in Sepang, a thickness of 6-8 inches (150-200mm) is typically recommended for medium use. For areas experiencing constant heavy loads or frequent heavy vehicle traffic, a thickness of 8-12 inches (200-300mm) may be necessary.

Q2. How often should an industrial concrete driveway be sealed in Malaysia's climate?

In Sepang's tropical climate, industrial concrete driveways typically require resealing every 1-3 years, depending on usage intensity and environmental exposure. High-traffic areas exposed to UV rays should receive new sealer every 2-3 years for optimal protection.

Q3. What are the key factors to consider when choosing a concrete mix for an industrial driveway?

When selecting a concrete mix for an industrial driveway, consider using grades between C30 to C40 for excellent compressive strength. The mix should incorporate angular aggregates for better joint performance and durability. The ratio of cement, sand, and aggregate should be tailored to the specific load requirements of your industrial application.

Q4. How can I ensure proper drainage for my industrial concrete driveway in Sepang?

To ensure proper drainage, industrial driveways in Sepang should be graded with a minimum slope of 1% (1 in 100) or 10mm per meter. The maximum recommended grade typically ranges from 1:4 to 1:6 (16.6% to 25%). Consider installing additional drainage solutions like French drains or grated trench drains for sites with challenging water management needs.

Q5. What should I look for when hiring a contractor for my industrial concrete driveway project?

When hiring a contractor, look for experience specifically in industrial concrete work, proper licensing, insurance, and bonding. Ask for references from similar industrial projects and verify their expertise in Sepang's climate conditions. Ensure they can provide detailed quotes, understand local permit requirements, and offer clear communication throughout the project timeline.

If your facility handles heavy traffic, cutting corners will cost you more in the long run. Our industrial concrete driveways are engineered for pressure, built for heavy loads, and designed to perform without failure—so your operations run smoothly, safely, and without interruption.

Choose strength. Choose reliability. Choose a concrete solution built to work as hard as your business does.

This isn’t residential concrete—it’s industrial performance built for businesses that refuse downtime.